MEANINGFUL WORK IN A PLACE THAT WE LOVE

Jasper Hill's mission is to make the highest possible quality products in a way that supports Vermont's working landscape. We are driven to be the standard bearer of quality and innovation in the artisan cheese industry while promoting our regional taste of place.

ONCE UPON A TIME

It all began when brothers Andy and Mateo, along with their wives, Victoria and Angie, pooled their life savings and bought a rocky hillside farm in Vermont's subarctic climate zone near the Canadian border. What made the Northeast Kingdom region special to them was the sleepy village of Greensboro with its sparkling, secluded Caspian Lake - where their family had found summer respite for more than 100 years.

Greensboro's sparse population and rural locale held few opportunities for conventional career paths. The old dairy barn they found themselves with hadn't seen cows for nearly 40 years. About a third of the farms in town sold their cows in 1998; the same year that the Kehlers bought what locals referred to as "the old Jasper Hill farm."

So from the start, Andy and Mateo realized their farm would have to be different. They set out to create a model for small-scale dairy farming that could offer more opportunities for Vermont's working landscape. The concept was called value-added agriculture: the practice of transforming a raw material like milk into something more valuable before it leaves the farm.

As the old barn got fixed up, they built a creamery next door. And because the highest value cheeses in the market were imported, European styles, they also created a cave aging space beneath for cultivating natural rinds. They worked on the pasture and made places for their young families to live. All in all, it took about 5 years of building structures and skills before they sent their first cheeses to market in 2003.

It was really hard. They didn't have a bulk tank or relief milker in the early days. Cows needed to be pastured and milked every day, and cheeses had to be made and tended to in ripening every day. Plus there was the work of packing little boxes with individual orders for dozens of individual shops and restaurants - and then chasing down all the invoices weeks later. Just as the bleak reality of their new life was setting in, they received an interesting phone call from their neighbors up the road at Cabot Creamery.

Cabot had noticed the early acclaim the Kehlers earned for their fancy little cheeses while watching the American Artisan Cheese movement pick up steam. They saw British bandaged cheddars popping up on new European-style service counters and on the country's best restaurant menus. Technically, and for a number of styles, Cabot made some of the best cheese in the country, and they had awards to show for it. What Cabot lacked was an aging space dedicated to cultivating natural rinds - their warehouses were all focused on keeping surface mold away from cheese. The Kehlers were nearby, hungry to grow their business, and most importantly had a temperature and humidity-controlled space designed to grow natural rinds. The result was Cabot Clothbound Cheddar.

At first, it was just a few racks of cheese, which were dutifully monitored and turned for a yearlong cycle of aging. The result was delicious, but a bit of a conundrum. The basement of the farmhouse creamery was nearing capacity, and it was hard to imagine growing the inventory needed to supply Cabot's core customers. With Cabot's blessing, Andy and Mateo shopped the new clothbound cheddar around to their direct accounts - shops and chefs who were used to dealing with fussy, high-maintenance cheeses.

The cheese was a success in unexpected ways - one of the first batches took home Best of Show at the 2006 American Cheese Society Conference. Not one to pass up an opportunity, Andy & Mateo took this achievement to the bank and drew up plans for an expanded aging facility beneath one of the pastures of Jasper Hill Farm.

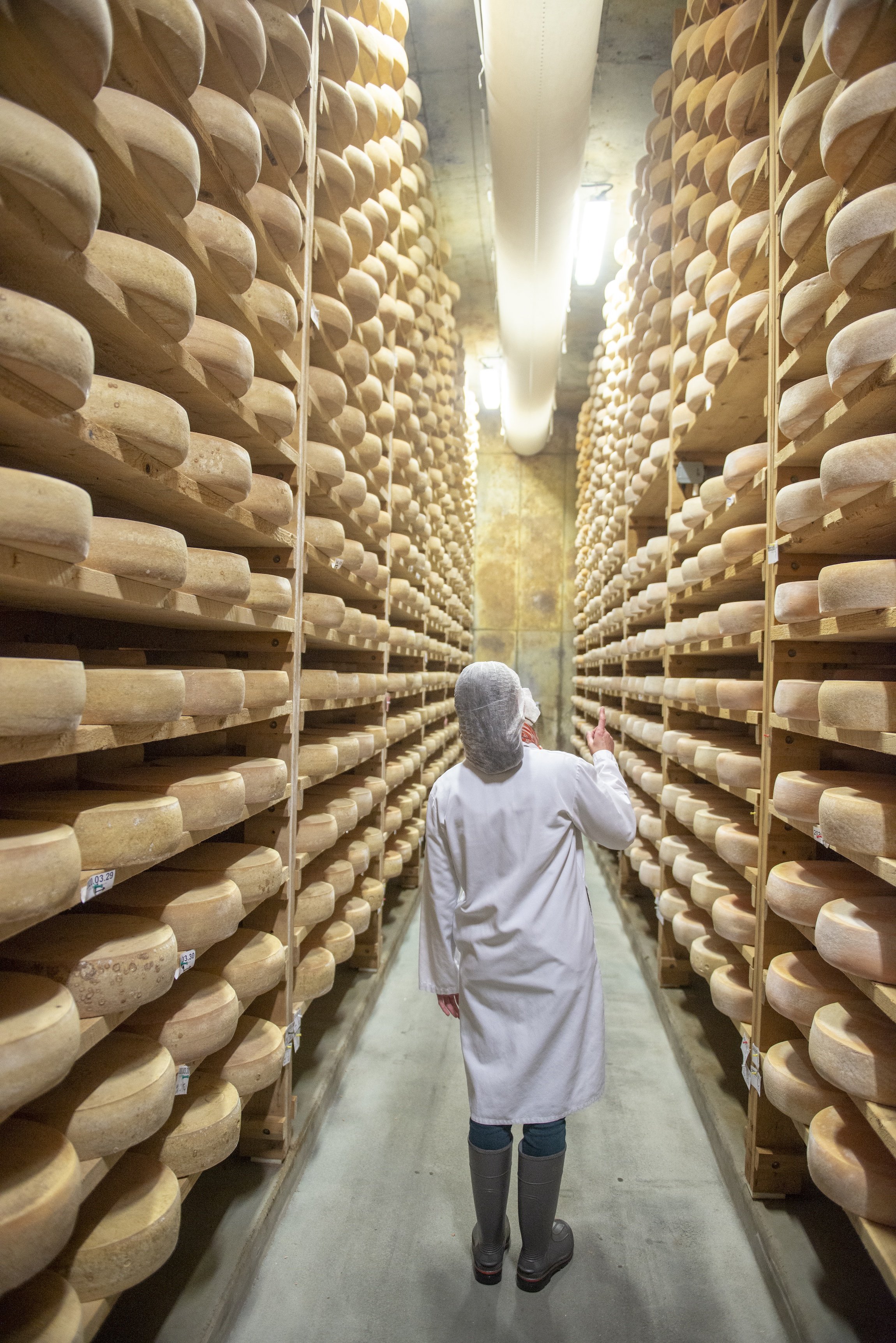

What came together over the course of the next two years is a 22,000-square-foot, 7-vaulted underground aging facility. Conceived as an infrastructure to reduce the barriers to entry for those interested in value-added production, the Cellars had plenty of shelf space for cheddar as well as more Jasper Hill Creamery and neighboring producers' products.

Ripening work for natural-rind cheeses takes up more than 70% of the labor for a batch of cheese, over its lifetime. By pooling these efforts, farmstead producers could spend more time focusing on the true drivers of cheese quality: milk production and cheesemaking. Instead of sending hundreds of small boxes through the post, refrigerated trucks now pick up pallets of cheese destined for regional and national distributors. The Cellars is now the final stop for cheeses coming from six different creameries. Its mission is to be the standard bearer for quality and innovation in the artisan cheese industry.

Cabot's initial support of this effort was multi-faceted and the volume and consistency of their products moving through the Cellars help maintain momentum and generate new opportunities for this growing, mission-based family of businesses: a nutrient recycler now reduces our footprint on the environment; our onsite microbiology lab helps us explore and amplify the concept of terroir within our collection; a conventional farm has been tailored to raw milk cheese production; a cropping center allows us to make high-quality feed in our challenging climate. All of these projects came about in the wake of this unlikely partnership, highlighting what makes Vermont's working landscape special.

The Kehlers and their growing network of collaborators look forward to an ever more diverse and thriving agricultural tradition in the Northeast Kingdom - one that creates a regional identity for the product developed to suit our region, culture, and ambitions for a sustainable future.

-

Transcript of: The Editorium - Jasper Hill Farm

updated 1/7/21

ANDY: Welcome to Jasper Hill Farm. We’re located in Greensboro, Vermont. We milk 45 Ayershire cows and turn all of our milk into a variety of artisan cheeses. We make blue cheeses, soft cheeses, stinky cheeses, you name it.

MATEO: Cheese is not an invention, it’s a discovery. And we’re pioneers out there on the fringe looking for something new. Our farm consists of an old-school tie-stall dairy barn attached to a fairly modern farmstead cheese plant where we process all our milk. We also ripem cheeses at the cellars at Jasper Hill, which is a one-of-a-kind underground aging facility. The building is really seven vaulted tunnels running back into the hillside.

ANDY: It’s built underground to be able to capture the temperature and humidity that is provided by the earth. And has the capacity to hold about a million pounds of cheese.

MATEO: A cheese will never be better than the milk that it’s made from and we go to some pretty extreme lengths to produce the best cheesemaking milk that we can.

ANDY: You can’t make a good cheese without good milk, right? You can’t make good milk without healthy animals. You can’t have healthy animals without a healthy landscape. And good feed.

MATEO: The microbial ecology of raw milk is the sum of the practices on a farm. So we built a microbiology lab to be able to understand those communities and the impacts that they have on the sensory qualities of our cheese. Jasper Hill Farm cheeses are available at all the best cheese shops in the United States. Lots of independnt cut-to-order cheese counters like Formaggio kitchen in Boston, Murray’s Cheese in New York, Cowgirl Creamery in San Francisco, Whole Foods market…Just about every counter around the country that has a legitamite cheese program is going to have our cheese.

ANDY: When the white house held a state dinner for the French President, they served our cheese, Bayley Hazen Blue. We were the only company that was called out by name, which was awesome.

MATEO: And then made fun of by Stephen Colbert.

SHEP SMITH: Jasper Hill Blue Cheese and Braised Chard.

STEPHEN COLBERT: Thank you Shep for that installmant of your award-winning segment: Reading A Menu.

MATEO: What makes me proud about Jasper Hill is—you know—that Andy and I built this place with our own hands

ANDY: We bought this farm because of an emotional attachment Mateo and I have to this place. To me, it’s paradise. Not just because it’s a beautiful place, but because it’s a beautiful community.

MATEO: Meaningful work in a place that you love with people that you love: that’s a whole life. And Bayley Hazen Blue really is the tastiest thing I’ve slid down my gullet.

-

Transcript- Dark Rye Productions

©2013 Whole Foods Market

MATEO: Most people don’t spend enough time or energy figuring out how to derive meaning from their daily existence.

Jasper Hill is really the culmination of a deep-seated yearning that both Andy and I have felt in our lifetimes to actually connect to a place.

Entrepeneurism is part of the backbone and the spine of the culture here. If you’re going to make a living up here you need to be enterprising. You need to be creative. You need to work harder. Local folks know how to scrap and scramble and carve out a living up here and have been for a couple hundred years. People who are living here are living here because they love the land.

ANDY: Mateo never really got along together growing up. I mean, we got along, but not really well I would say.

MATEO: I used to beat the crap out of him all the time. It was terrible. Our parents are completely, like, amazed and proud and happy that, like, we figured out how to work together and live together. We are the product of our parents. Our father is like a serial entrepeneur. And our mother is fiercely committed to social justice. Having grown up in Columbia in the 70’s and 80’s where we were surrounded by extreme poverty and ridiculous wealth and we fit in there somewhere in the middle. It brought a different kind of perspective and a responsibility for taking care of the folks around us.

Jasper Hill is really the result of a quest for meaningful work in a place that we love. Our family has a connection to Greensboro going back about 100 years.

ANDY: Mateo and I have a real emotional attachment to Greensboro. This is where we spent our summers. And the happy sort of child hood memories happened in this community. The year that we purchased this farm in 1998, Greensboro lost 30% of its dairys. There isn’t a lot of economic activity that happens in our town outside of agriculture and the timber industry. So the loss of those dairys had a really significant impact on the fabric of our community. If we wanted this place to look and feel like it did in our youth, we were going to have to create these new opportunities.

I think when we first started in on our business, we were really excited. I mean, we had committed, we had jumped in with both feet. We’re going to build this company, we’re going to be milking cows, and I think that the community lined up to watch a train wreck. I don’t think there was any animosity behind it, but I think there were a lot of people who were skeptical.

MATEO: We built buildings. We got the cows bred, we started milking them.

ANDY: And it was just the two of us. It was about 18 months before we got a day off. If you’re going to work this hard it might as well be for something you love that wants to get you out of bed in the morning, because we get up kind of early.

MATEO: The cheese has to be delicious in order for us to meet our social mission as individuals and as a company. Tasting is what we do here. We taste every cheese that goes out the door. It’s how we connect with the product. Cheese is like a rabbit hole, I mean you can go deep. It’s a great marriage of craft and science. That’s what makes it interesting: that there’s always a new challenge.

ANDY: Our personal relationship has changed a lot over the years. We had to learn how to work through our differences, and how to communicate, and how to compromise and be able to come to agreements.

MATEO: I think we trust and appreciate what each of us brings to the table and we don’t compete. I’m pretty good at finding cliffs and jumping off of them. And he’s pretty good at stitching up the parachute so we don’t crash and burn. This business is really the product of our partnership and would be radically different if one of us was missing.Description text goes here